Production

Home

- / GIG Karasek Portfolio Overview

- / Production

High-quality key components and high-performance high-pressure equipment with „Made-in-Austria“ quality

Installation of a rotor in the GIG Karasek workshop in Attnang-Puchheim, Austria © GIG Karasek

Join us on a short tour through the GIG Karasek Workshops

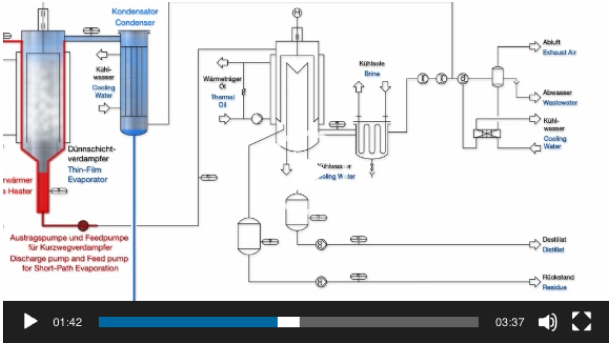

GIG Karasek manufactures its key components and special high-pressure equipment in Austria. In Gloggnitz, we focus on our falling-film evaporators and lamella production. In Attnang-Puchheim, components for thin-film and short-path technology are manufactured in particular.

Reliability through quality

Both workshops are well equipped, approved in accordance with current international design and manufacturing standards, and all our products are subjected to stringent testing procedures before being used in the plant.

Because, like our customers, we also have the highest standards when it comes to quality!

Interested to learn more? Book a meeting and discuss how you can benefit from our in-house production capabilities.

Materials

-

Rust/acid-resistant steel grades

-

Duplex steel

-

Fine-grained structural steel, low-carbon, high-temperature, and heat-resistant steels

-

Plated steel grades

-

All nickel-based alloys

-

Titanium grades 1, 2, 7, 11

Surface treatment

Pickled, passivated, sanded and electropolished Ra < 0,4 μm

Standards

- Certifications: DGRL 2014/68/EU, AD2000 HP0, EN ISO 3834-2, EN 1090-2, ASME VIII-1, CML

- Test procedures: VT, PT, MT, RT and UT

Cylinders with a diameter of up to 4,300 mm and components with a unit weight of up to 120 tons can be produced in the GIG Karasek Workshops.

GIG Karasek Lamella Technology

The production of lamellas for plate falling-film evaporators has been one of our core competencies for decades and is constantly being developed further.

The heating elements are produced in our state-of-the-art inhouse lamella production facility in Gloggnitz, Austria.

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.