When operating evaporation plants using the sulfite process, deposits of substances accumulate on both sides of the heat exchanger, which permanently disrupt the operation of the plant. Therefore, cleaning the evaporator plays a decisive role in achieving a reliable process and ensuring the long-term operability of the evaporation plant.

Gypsum and furfural deposits in the sulfite process

In the sulfite process, the fouling of the heat exchanger is an important issue. Even thin layers of less than 0.5 millimeters can significantly reduce heat transfer and, therefore, the evaporator performance.

Most of the deposits on the heat exchanger surface of the medium requiring evaporation, are gypsum deposits. Deposits of furfural develop on the surface of the heating medium (vapor) because of the chemical nature of the medium.

To reduce the adverse effects of these deposits, it is necessary to clean evaporation plants regularly at high operational costs. Cleaning is carried out differently for both the medium and the heating steam side.

Cleaning the medium side (gypsum)

Gypsum deposits that form on the caustic side of the heat exchanger can develop into incrustations due to residual fibers in the caustic, which stick to the heat exchanger as if they were burnt together. Regular rinsing is part of the operating program, and mechanical cleaning during the annual shutdowns.

1. Regular washing cycles

Regular washing cycles with vapor condensate or thin liquor ensure efficient operation and uniform evaporation. In addition, the solubility of gypsum in self-condensate/thin liquor is utilized to remove the gypsum deposits.

Most evaporators have a Cleaning-in-Place (CIP) system installed to control the wash cycles. The interval between rinses depends on the concentration in the respective evaporation stage. Highly concentrated evaporation stages are usually switched from caustic operation to rinsing operation every eight hours, while one to two rinses per month is sufficient for lower concentration stages.

Note: In principle, rinsing chemicals can also clean the leach side, but only during a shutdown. Conventional methods include cleaning with self-condensate or thin caustic solution during operation.

2. Mechanical cleaning at standstill

After an extended operation period, despite regular flushing, a deposit builds up on the evaporator surface, which must be removed from time to time. Therefore, the heat exchanger is mechanically cleaned using high-pressure spray lances, tank cleaning equipment, or special heat exchanger cleaning tools during routine shutdowns. Cleaning usually takes several days and can be carried out within the time frame of a normal shutdown.

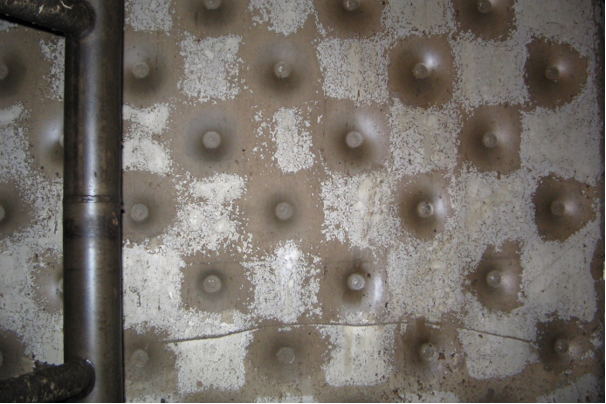

A self-cleaning effect and flaking of the plaster coating in the falling film evaporator © GIG Karasek

Cleaning the heating steam side (Furfural)

The heating steam side is cleaned chemically with nitric acid or hydrogen peroxide during the shutdown. In addition to the standard safety measures, it is essential to wear protective clothing when cleaning with nitric acid. Furthermore, it is necessary to ensure that the reaction gases produced are discharged to prevent an impermissible increase in pressure in the plant:

- Cleaning with nitric acid produces toxic nitrous gases, which must be thermally disposed of via a boiler.

- The reaction gases with hydrogen peroxide are unproblematic and may be released into the atmosphere.

Handling nitric acid requires appropriate protective clothing and strict adherence to work instructions © Tanakorn / stock.adobe.com

Comparison of cleaning properties of tube type - and plate falling film evaporators

In the sulfite process, tube type and plate falling film evaporators are primarily used. As far as cleanability is concerned, there are considerable differences, which we would like to discuss in brief.

1. Tube type evaporator

As soon as incrustations form in the pipes, they can no longer be rinsed away. In addition, mechanical cleaning of these incrustations is problematic because the pipe falling film evaporator can only be accessed from above. Therefore, optimal cleaning over the entire heating surface is difficult.

Tube type evaporators have a tendency to block when exposed to a fouling media © weerapong/stock.adobe.com

2. Plate falling film evaporator

The main advantage of the plate film evaporator is the leach located on the outside of the heat exchanger. In addition, the walk-through nature of the evaporator and the large spaces between the plates mean that the soiled surfaces are easily accessible and can be efficiently cleaned both mechanically and chemically.

The plates also have a self-cleaning effect that continuously reduces plaster deposits even during operation. As soon as the evaporator is activated to flush, there is a change in the heating surface temperature, which causes the plaster deposits to flake off. Due to this self-cleaning effect, only a little or no incrustation occurs. In addition, the droplet separator integrated into the evaporator can also be cleaned easily, ensuring high condensate quality.

The accessibility of plate fall film evaporators makes cleaning much easier. © GIG Karasek

Correct layout of the evaporator reduces deposits

With the appropriate layout of falling film evaporators, fouling caused by sulfite liquors cannot be prevented but can be minimized. Three factors, in particular, play a significant role in this respect:

- Temperature: Fouling on the leaching side can be reduced by limiting the temperature in the highly concentrated stages to about 125 degrees Celsius. The reason is that deposits and incrustations massively increase at higher temperatures.

- Impact: Contamination on the caustic side can be minimized by selecting the proper

circulation rates (= effective wetting). - Heating surfaces: An additional consideration is to design the heating surface so that its load is not too high and not too much is evaporated per square meter of heating surface. Accordingly, larger heating surfaces are beneficial for reducing deposits with minor temperature differences. However, investment costs and operating costs have to be taken into consideration.

Ultimately, deposits cannot be wholly prevented in caustic sulfite solutions. Still, there are ways of minimizing fouling by observing the temperature, the impact, and the size of the heating surface.

Conclusion: Cleaning evaporation plants in the sulfite process

Deposits in evaporation plants used in the sulfite pulp industry must be regularly cleaned to maintain the evaporation capacity.

Plate falling film evaporators are designed to meet these requirements as the plates have a self-cleaning effect that facilitates vapor condensate cleaning. In addition, the accessibility of the plate falling film evaporator significantly improves the opportunities for mechanical cleaning compared to the tube type evaporator.

However, regardless of the type of evaporator, it is ultimately important that the evaporators are regularly and thoroughly cleaned mechanically or chemically, with vapor condensate at least once a year during a shutdown. Permanent deposits are very costly and result in reduced plant efficiency.