Conventional Evaporation Technology

Home

- / Overview Evaporation Technology

Suitable for high evaporation rates, substances with low viscosity and low thermal sensitivity

Different types of evaporators and process solutions for individual requirements

Plate Falling Film Evaporator

Tube Falling Film Evaporator

Multiple Effect Evaporation Plants

Mechanical Vapor Recompression (MVR)

Thermal Vapor Recompression (TVR)

Fields of application

Temperature: ≤ 200°C

Vacuum: ≥ 80 mbar abs.

Feed: 500 kg/h to 700,000 kg/h

Viscocity: ≤ 250 mPas

Performance: ATEX, GMP, API

Materials: Carbon steel, Hastelloy, titanium, stainless steel (1.4301, 1.4306, 1.4307, 1.4404, 1.4432, 1.4436, 1.4462, 1.4571, 1.4539 and more)

GIG Karasek has focused its concentrated know-how in process engineering and apparatus engineering on perfecting falling film technology. The plate and tube falling film evaporators are ideal for high evaporation rates, substances with low viscosities and low thermal sensitivities.

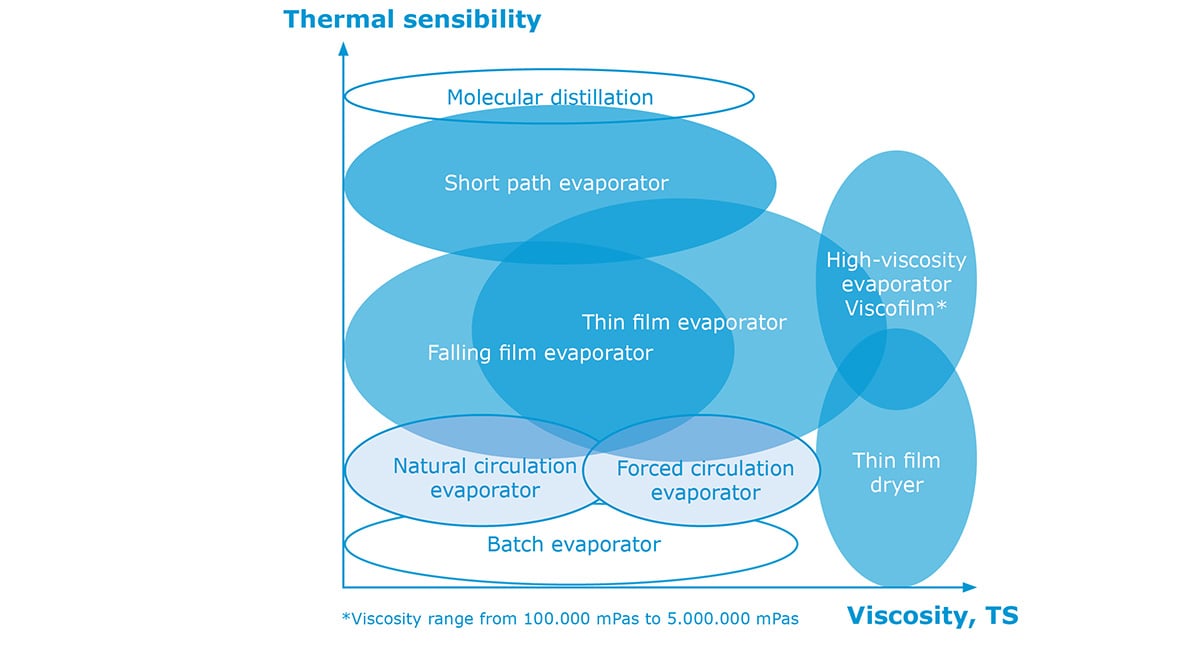

The following diagram shows the respective areas of application in evaporation technology.

By choosing or combining the right technologies, GIG Karasek is able to handle a very wide range of different substances.