CompriVAP - Industrial Heat Pump Solution

Home

- / GIG Karasek Portfolio Overview

- / Industrial Heat Pump Solution

On the way to decarbonization with industrial waste heat utilization

Electrification of steam production

We support our customers when it comes to:

- Reduction of energy consumption

and dependence on fossil fuels - Reuse of waste heat streams

for plant-internal or external processes - Significant increase of plant efficiency

In energy-intensive industrial sectors a significant portion of the energy used is still largely discarded as unused waste heat via exhaust steam or wastewater. Furthermore, cooling down/additional energy input is needed for environmental release.

CompriVAP OPEX calculator – your industrial heat pump project at a glance

The CompriVAP Operating Cost Calculator is a powerful tool that provides a solid basis for decision-making when planning and investing in an industrial heat pump.

Click below to try it now, gain valuable insights, and uncover potential energy savings for your facility!

© GIG Karasek

GIG Karasek offers a powerful process to harness the massive potential of surplus thermal energy. Our highly advanced CompriVAP industrial heat pump system recovers and reuses vapor – this is the best and still most commonly used medium for conveying heat in industrial processes.

Functional principle

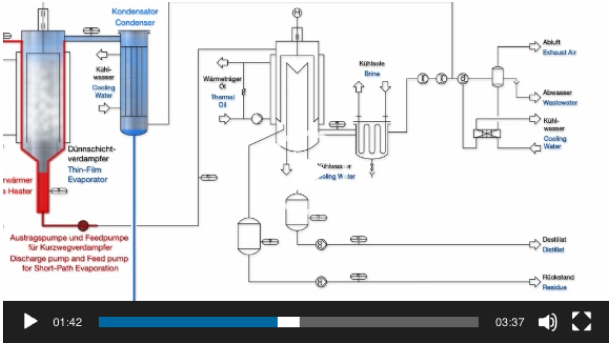

The CompriVAP system is an industrial heat pump solution that is based on well-established MVR (Mechanical Vapor Recompression) technology and is particularly well- suited for low-temperature waste heat streams. Process steam is drawn in by an electrically operated compressor and raised directly to a higher energy level by increasing the pressure. Heat sources might be warm liquid streams or vapor, which are often not useful as such but still contain a significant amount of energy.

The type of application, the properties of the heat source and the required parameters of output steam define the specific setup of the system. It might consist of just one machine or several compressors. When using waste liquid as a heat source, a flashing stage is needed.

ADVANTAGES:

- Reusing liquid and gaseous waste heat results in a reduction of primary energy demand and subsequently also reduces CO2 emissions

- Resources are used economically - less fresh steam and cooling water is needed

- High potential for OPEX savings is a given

- (Retrofit) installation is straightforward and fast

- Mature technology, already available for use on large industrial scale

Team up for industrial waste heat utilization and to achieve decarbonization goals such as the European Green Deal.

Potential waste heat sources

-

Reuse of liquid waste streams like waste water, process condensate, etc. with vacuum flashing

-

Utilization of gaseous waste media like exhaust air/gas, process gas, etc.

Why work with GIG Karasek?

We have been experts in industrial equipment and plant construction for decades and have a comprehensive know-how on the installation of several MVR applications in various industries. Our process expertise and the ability to complete various project types – whether it be pilot plants, skid units and turnkey plants on EPC basis – make us the right partner in waste heat utilization.

How we support you

-

Detailed evaluation of available waste heat

-

Tailored process design comprising open or partly open process circuits

-

Careful selection of compressors from different OEMs

-

Detailed planning of necessary compression stages

-

Fact-based evaluation of CAPEX and OPEX aspects

Our scope of supply includes the following services:

-

Process design

-

Basic- and in-detail engineering

-

Compressors, auxiliary equipment, and spare parts

-

Vapor ducts and piping

-

Flash tank (if needed)

-

Instrumentation

-

Installation and supervision

-

Commissioning and startup support

Exemplary layout of the CompriVAP industrial heat pump system with a six-stage compressor plant. © GIG Karasek

Retifikation

Übersicht

Einsatzgebiete

- Alkohol / Wasser

- Lösemittel / Wasser

- Lösemittel / Fettsäuren

- Trichlorethylen / Öl

- Lösemittel / Wasser aus Spinnbad für Faserindustrie

- Alternative Treibstoffe

- Methanolabscheidung aus Kondensat der Eindampfanlage

- Methanol / Wasser

- Ethanol / Wasser

- Aceton / Wasser

- Butylacetat / Wasser

- Butylalkohol / Wasser

- Glycerin / Wasser

- Milchsäure / Wasser

uvm.

Vorteile

- kontinuierliche Betriebsweise

- energetisch günstiger als eine Destillation

- platzsparend

- technisch weniger aufwändig

Energieoptimierungsmöglichkeiten

- Mehrstufige Anlagen

- Mechanische Brüdenverdichtung

- Thermische Brüdenverdichtung

Kolonneneinbauten

- Packungen

- Böden

- Füllkörper

Reboiler

- Fallfilmverdampfer

- Dünnschichtverdampfer

- Zwangsumlauf

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.

Download

Visit our Newsroom!

Here you can find the latest NEWS, our EVENT CALENDAR or further INSIGHTS featuring our key topics.

We’ve also published the following articles on the topic of waste heat utilization:

Industrial Waste Heat Utilization: Heat Recovery Options in Pulp Mills

Efficient Use of Waste Heat: Industrial Heat Pumps as a Driving Force of the Energy Transition

Industrial Heat Pumps in Comparison: Technological Differences and Application Areas

CompriVAP Heat Pump Solution: Turning Waste Heat into Value