Digitalization and IIoT

Home

- / GIG Karasek Portfolio Overview

- / Digitalization and IIoT

With the GIG Karasek digitalization platform to the optimum operating point of your system

Bring your systems to the digital pulse of time

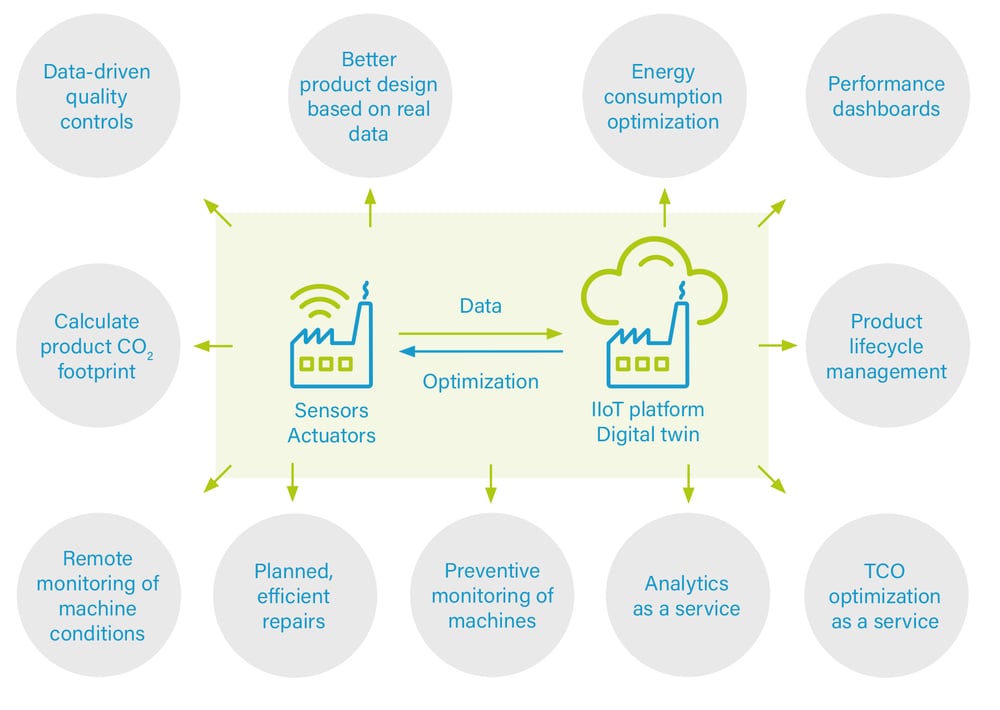

With the GIG Karasek platform, customers have the opportunity to digitalize and monitor their production processes and, above all, to bring them to the best possible operating state.

In addition, we also use various modern Smart Services, which are excellent tools for increasing efficiency and saving costs and resources.

GIG Karasek pay-per-use – flexible financing solutions that adapt variably to the respective system usage – are available to support system operators with more flexibility and lower investment risk, even in economically challenging times.

Interested to learn more? Book a meeting and get a deeper understanding of state-of-the-art digitalization methods.

Advantages

-

Increases the efficiency of the system

-

Saves costs and resources

-

Predictive operation – real-time information and long-term trends

-

State-of-the-art IIoT (Industrial Internet of Things) platform

-

Secure data handling and strict access controls

-

Intuitive operation of the IIoT platform

-

Certified hardware devices

Smart Services

Digital Twin

Virtual model of a plant

Probably the most extensive application in the field of digitalization currently consists of mapping equipment or entire systems as virtual "digital twins" and storing them with comprehensive documentation.

Condition Monitoring

Monitoring and analysis of process parameters

Condition monitoring refers to the continuous monitoring and evaluation of the condition of machinery and equipment in order to detect potential problems at an early stage and take preventive action. Various parameters such as vibrations, temperatures, pressure conditions, noises, or electrical signals are continuously recorded and analyzed.

Predictive Maintenance

For when servicing is needed

Predictive maintenance is a service for effective maintenance of equipment and machinery that uses algorithms and machine learning models to analyze data and make predictions. Based on these predictions, the optimal time for maintenance measures can be determined. GIG Karasek is currently developing individual predictive maintenance models for its single equipment.

Optimization as a Service

Improvement of production sequences and energy consumption

OaaS (Optimization as a Service) provides valuable insights into a system's operational behavior and characteristics. It is based on a combination of data analysis and joint meetings to identify optimization potential and make appropriate adjustments in a targeted manner. The aim again is to keep the system's performance, efficiency, and yield at the highest possible level – even when requirements change – while reducing costs.

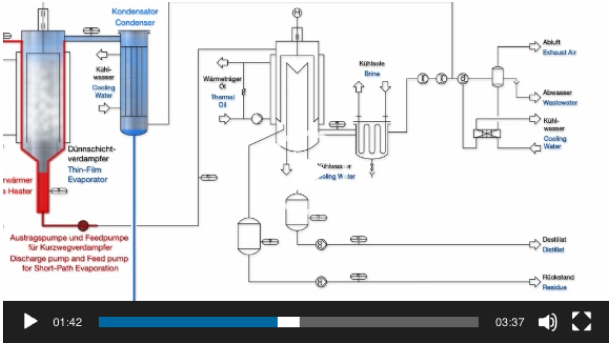

Measurement data monitoring – Example illustration of a process plant

© GIG Karasek

IIoT enables a wide range of smart services. In-house illustration. © GIG Karasek

Visit our newsroom!

Here you can find the latest NEWS, our EVENT CALENDER or further INSIGHTS on key topics.

We've also published the following articles on the topic of digitalization:

GIG Karasek Embraces Digitalization with an Innovative IIoT Platform

GIG Karasek Pay-Per-Use: Flexible Financing for Plants in Dynamic Markets

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.